Tap Drill Size and Different Types of Threads

Choosing the right tap drill size to achieve the optimum size of thread taps is crucial. However, it’s not as easy as it seems. Usually, it’s considered a major problem for many design manufacturers and thus end up...

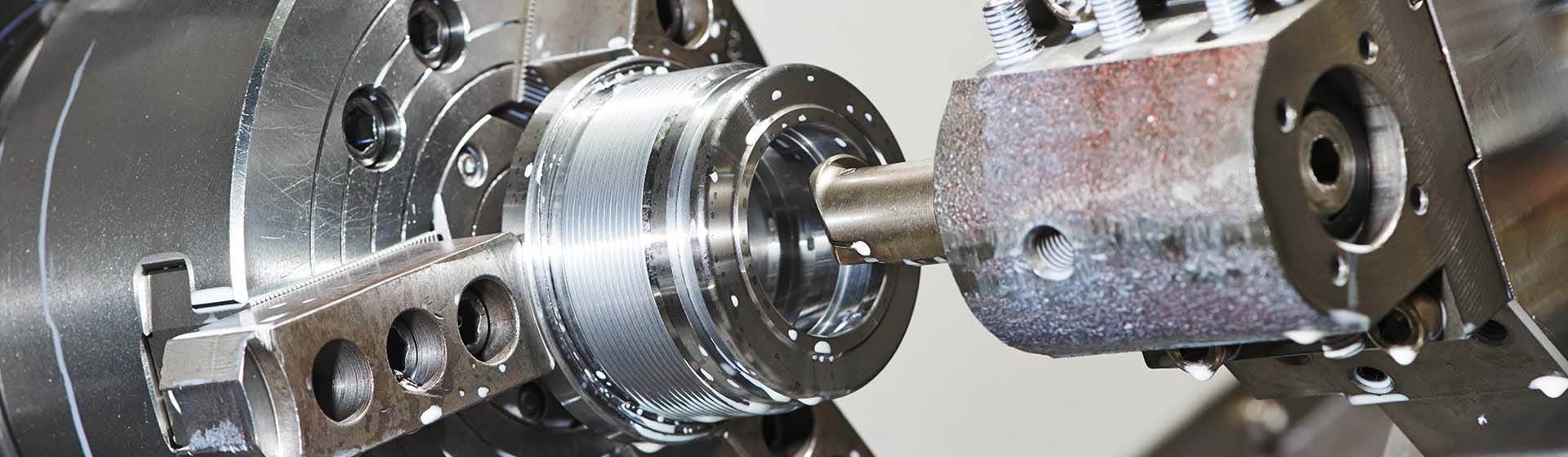

CNC Milling Machine Parts and Their Function: A Comprehensive Overview

Today, it is impossible to imagine the world of precision manufacturing without CNC (Computer Numerical Control) milling machines. It has become the go-to process in manufacturing due to its ability to manufacture complex parts...

What is CNC Precision Machining? A Comprehensive Technical Guide

At the core of modern manufacturing is accuracy and efficiency; CNC Precision Machining plays an indispensable role here. Used from aerospace to medical devices, it has become an integral technology. But what is CNC Machining, ...

The benefits of using overseas cnc custom parts manufacturing

In the innovative world of manufacturing, getting parts as fast as possible and on the cheap is the most important thing for one to stay competitive. With the growing trend, most of the automotive and aerospace companies are no...

Everything You Need To Know About Aluminum Anodizing

Aluminum Anodized Motorbike Clutch Image Description: Several aluminum anodized motorbike clutch parts are neatly arranged on a surface. Are you frustrated with aluminum products that scratch, corrode, or lose their shine over ...

What Is Fiber Glass? A Comprehensive Guide

Fiber Glass Fabric Image Description: White fiberglass fabrics placed together in raw form. Fiberglass must be familiar to everyone, from surfing enthusiasts to swimmers and every commuter who uses a car. Industries widely use ...

Hand Tapping Vs. Machining Thread: How To Choose Between

To select the optimum threading technique, it’s important to understand the benefits of each option. Hand tapping offers a manual solution. It’s best for low throughput use. Moreover, it provides accuracy, and exact precision ...

What Is Lathe Machine and What Does a Lathe Machine Do?

Interrogating machine tools presents the lathe in the list of prominent players. These are multi-purpose tools that mold items into precision shapes. Generally, lathe machines are used in watch-making and aerospace sectors. In ...

Machining Tolerance Fit Explained

Measurement of Steel Ball Bearing by a Precise Analog Caliper Image Description: The image shows a precise analog caliper being used to measure the diameter of a steel ball bearing. The caliper jaws are gently positioned aroun...

8 Ways to Avoid Burrs in Aluminum Extrusion

Burrs are one of the common defects that may be experienced when dealing with aluminum extrusions. They occur as rough ridges or edges on the aluminum profile caused by processing operations like milling, drilling, engraving, p...